Customized Non Standard Carbide Two Head End Mill Cutting Tools

CHANGZHOU AITEFASI TOOLS CO., LTD.- Coating:Coating

- Tooth Form:Spiral Tooth

- Structure:Integral

- Material:Cemented Carbide

- Type:Vertical Milling Cutter

- Flute Diameter:0.3-40mm

Base Info

- Model NO.:eitfs2149

- Shank Diameter:4-40mm

- Over All Length:38-330mm

- Transport Package:1PC,1 Plastic Tube

- Trademark:eitfs

- Origin:China

- HS Code:8208101900

- Production Capacity:3000 Piece,Pieces Per Month

Description

Products Features

1. Special Cutting Edge: Special cutting edge can increase the cutting ability. The lifetime of tools and machines will be longer

2. Smooth And Wide Flute: Smooth and wide flute will remove the cuttings more easily

3. Heat-resistant Coating: With highly heat-resistant HELICA coating, can be used for high-speed processing

4. Bronze Coating: Under bronze coating, any abrasion is easy to be recognized

5. High Quality Raw Material: The raw material is used of high toughness, grain-sized carbon tungsten

6. Polished Surface Treatment: With high polished surface treatment, reduce the friction coefficient could be reduced, the lathe efficiency could be improved, more production time could be saved

Our Advantage

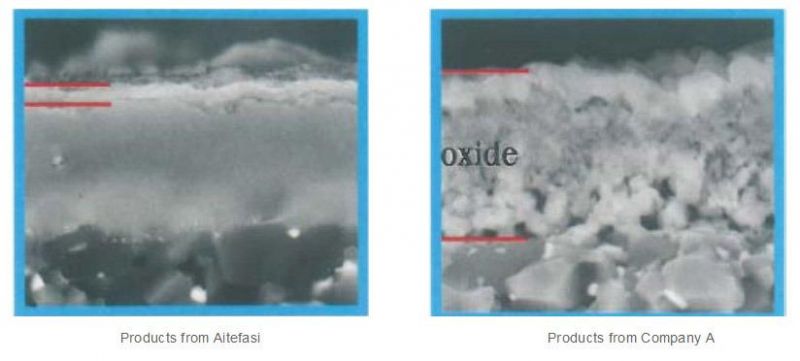

1.Perfect oxidation resistance in high temperature 1100ºC

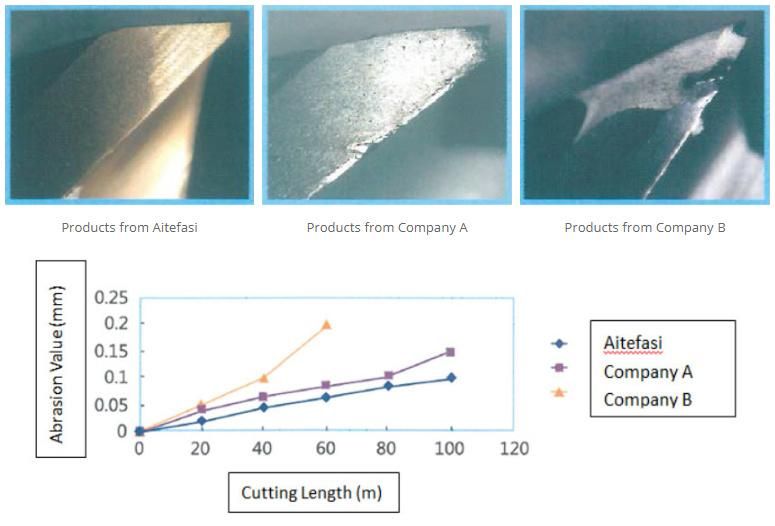

2. Abrasion condition of side cutting edge after processing 60m

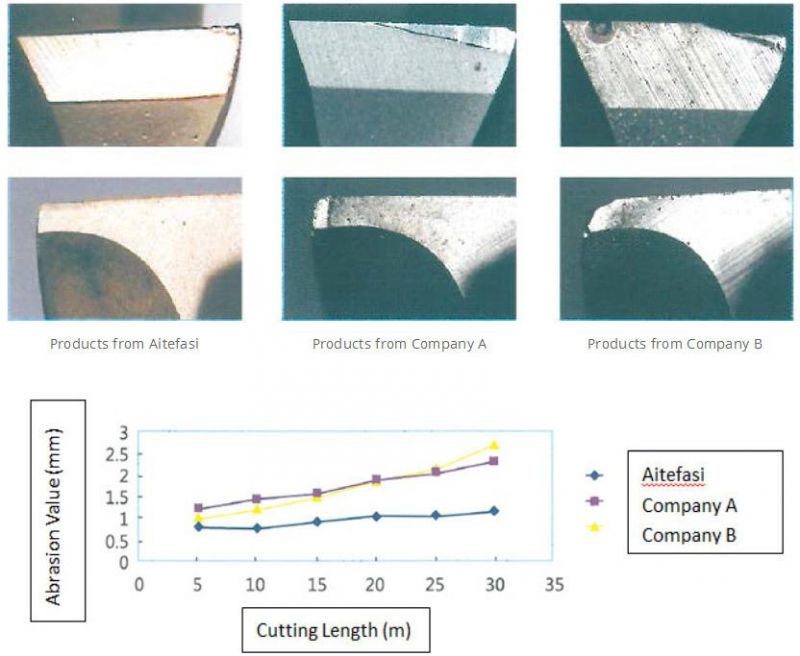

3. Abrasion condition of top cutting edge after processing 60m

Why Choose Us

Quality Assurance | OEM&ODM | Our Service |

Strict quality process covers every step. | Custom cutting tools can be designed. | 24 hours on line support can be provided. |

Clients Good Feedback

We would like to compare yours against others. They work much better than previous tools we

have ever used. The 12mm 3 flute end mill were used for processing aluminum for 600 meters. The lifetime is so long. We will order more.

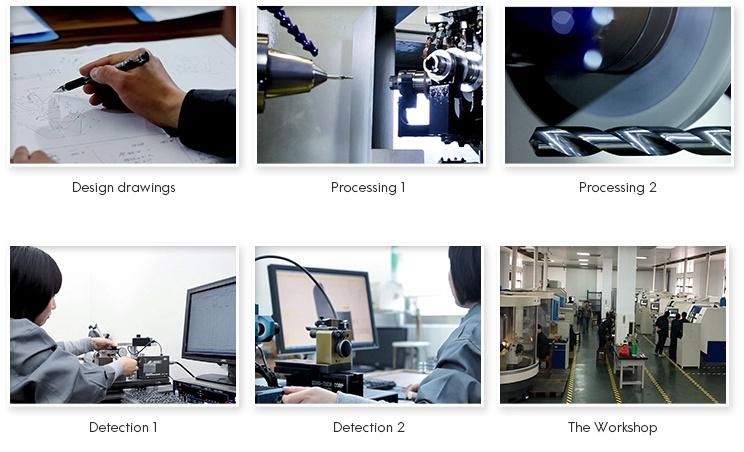

Production Process

EXHIBITION

FAQ

1.Delivery Time: 5-10 Working days

2.Payment Terms:T/T, Paypal, Western Union, AliExpress.

3.Shipping Terms: DHL. FEDEX, UPS, TNT, EMS.etc. according to your demand.

4.Main Markets: Germany,Italy, France,Spain, Russia, Australia, Brazil, Canada,USA, Mexico, Czech, Poland, Turkey and so on.

5.Product Positioning: Aitefasi quality is similar as Germany advanced brand quality.

High Quality with Reasonable Price. Welcome send inquiry to us.