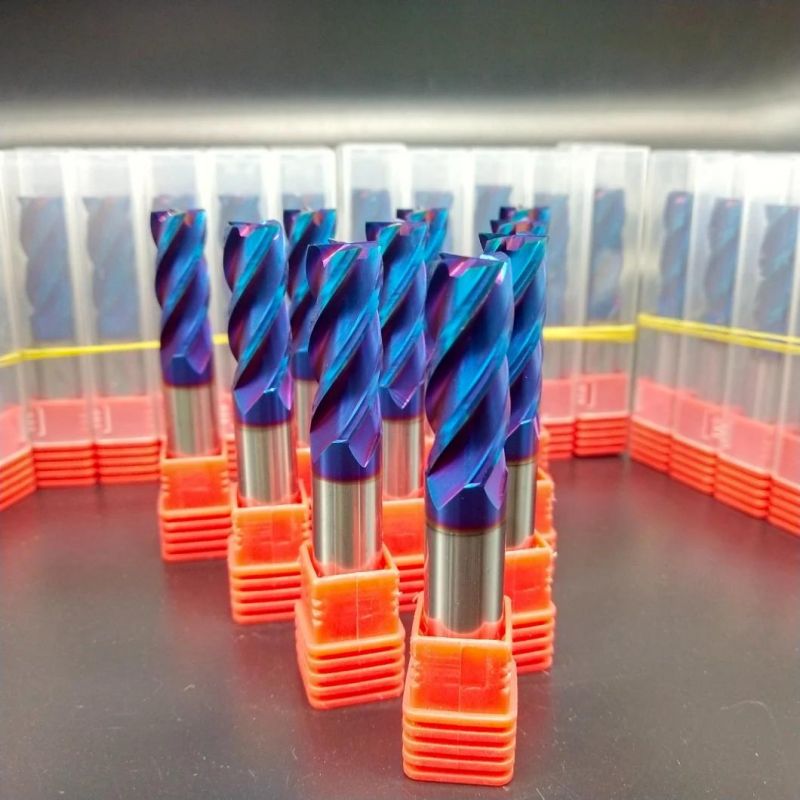

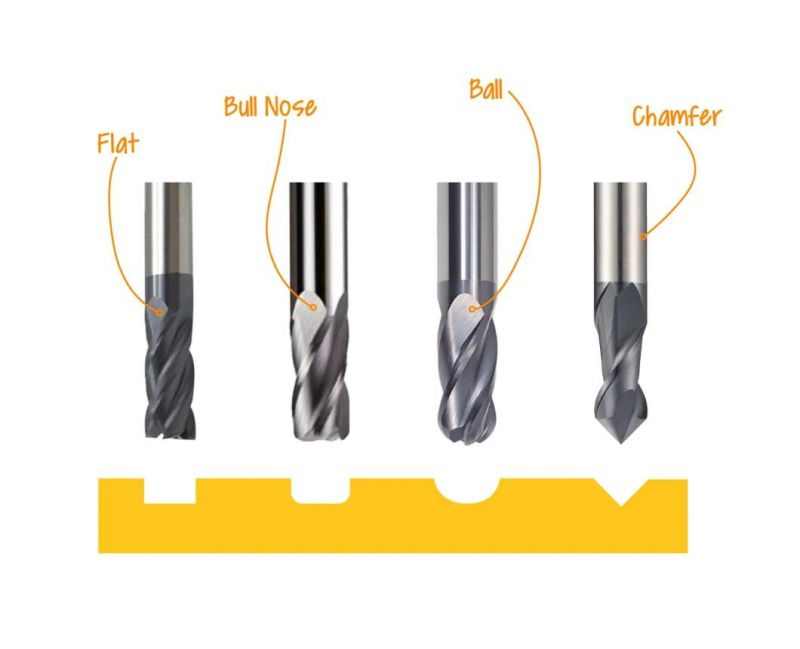

Carbide End Mills with excellent cutting edges

Solid Metalworking LNC. Limited- Tooth Form:Spiral Tooth

- Tooth Space:Sparse Tooth

Base Info

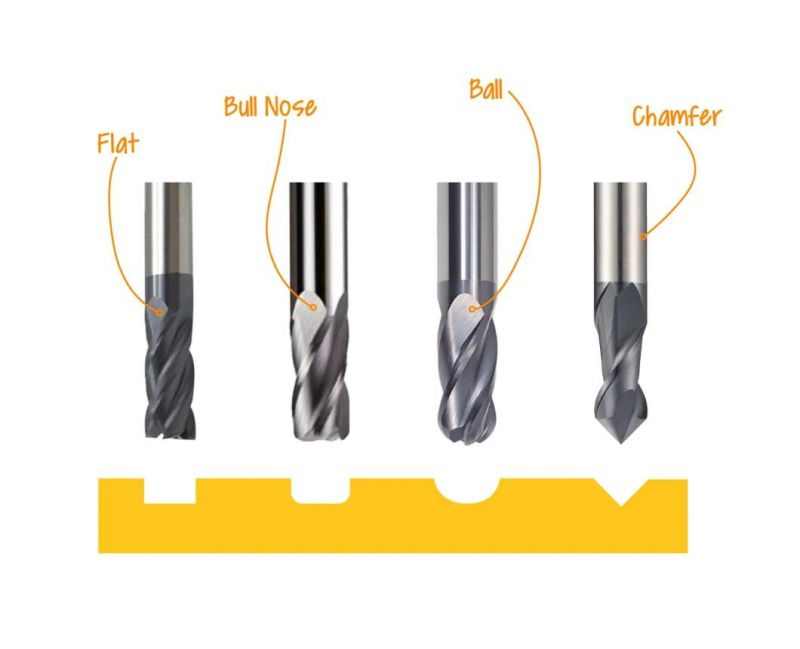

- Model NO.:Square-Ball-Corner Radius

- Structure:Integral

- Material:Cemented Carbide

- Type:Vertical Milling Cutter

- HRC:HCR45,HRC55,HRC60,HRC65 and etc

- Logo Engrave:Acceptable

- Brand:EXCELLEDGE

- OEM Custom:Acceptable

- Sample:Available

- Delivery time:2-5 working days

- Shipping ways:DHL,Fedex,TNT,UPS and etc

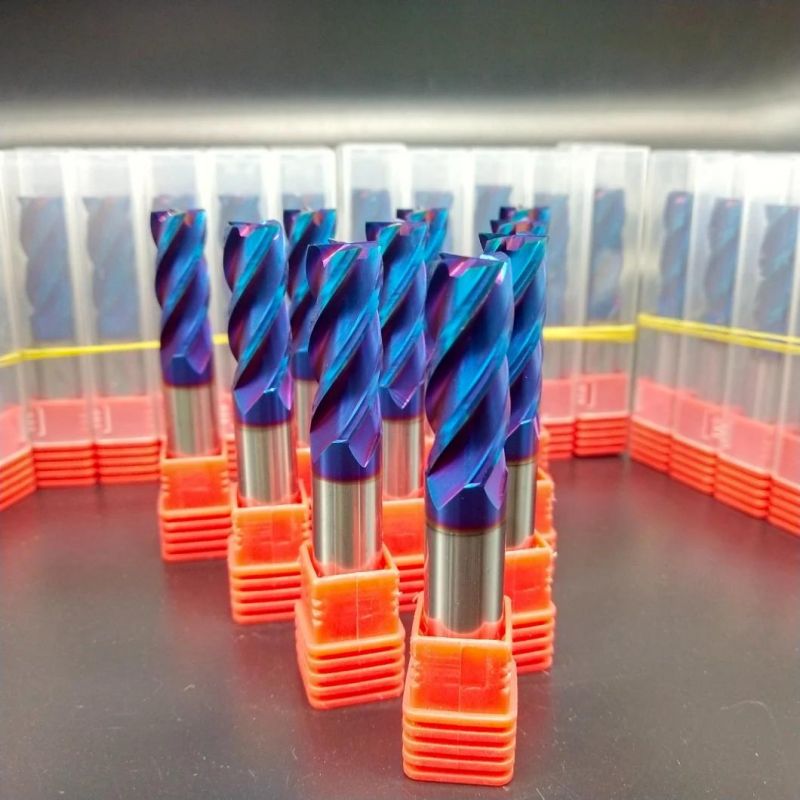

- Transport Package:Plastic Box

- Specification:ISO

- Trademark:Excelledge

- Origin:Chengdu, China

- HS Code:8208109000

- Production Capacity:80, 000 PCS,Month

- Package size per unit product:16.00cm * 1.50cm * 0.60cm

- Gross weight per unit product:0.250kg

Description

HRC45/55/60/65Coating Type ALTIN /TIALN /TISIN /NACO /DLC /Diamond OEM Acceptable Application processing of copper, cast iron, carbon steel, mould steel, stainless steel, titanium alloy, tool steel, and heat-treated steel and etc

Characteristic

CharacteristicHardness(HV) 3300 2800 4300 42(GPA) Thickness(UM) 2.5-3 2.5-3 3 3 Oxidation Temp.(°C) 900 800 1000 1200 Friction Coefficient 0.35 0.3 0.25 0.4 Color Black Dark Purple Copper Blue Advantages High heat stability Normally cutting Suitable for heavy cutting, and high hardness cutting For high precision cutting Suitable for high speed, dry cutting Suitable for cutting mould steel, stainless

steel Suitable for high hardness cutting, mould steel processing Most suitable for carbide cutting tools, turning insert

Packaging & Shipping

Characteristic

Characteristicsteel

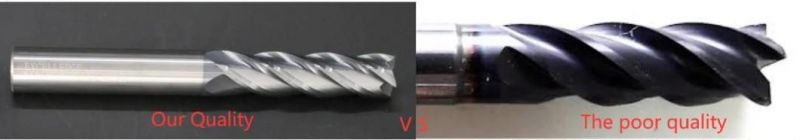

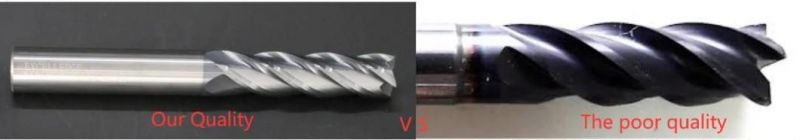

What is the advantage of our End Mill ?

1. Material: 100% virgin raw material with submicron grain size;

2. Grade: Various grades for choice;

3. Advanced production equipments and testing equipments

4. Precision Ground and polished;

5. High wear resistance,high hardness and impact toughness;

6. Advanced technology , automatic pressing , HIP sintering and precision grinding;

7. Samples & small orders are acceptable.

Packaging & Shipping