Gw Carbide-CNC Machine Tungsten Carbide 4X10X50mm Blue Nano Milling Cutter

Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd.- Coating:Coating

- Tooth Form:Spiral Tooth

- Tooth Space:Sparse Tooth

- Structure:Integral

- Material:Cemented Carbide

- Type:Cylindrical Milling Cutter

Base Info

- Model NO.:All size

- Length:50mm-150mm,Customized

- Cutting Form:Corner Radius, Roughing, Ball Nose, Flat

- Usage:General High Speed Cutting

- Coating Type:Tisin, Tialn, Altin, Ticn, Blue Nano

- Work Piece:HRC 45, 55, 60, 65, 68

- End Mill Flute:1,2,3,4,5,6,8,12

- Flexural Strength:2500-4000n,mm2

- End Mill Flute Diameter:D0.2-D30mm

- End Mill Flute Length:1mm-300mm

- Delivery Time:7-15 Days

- Transport Package:Standard Box

- Specification:33x23x19cm

- Trademark:GW

- Origin:Zhuzhou

- HS Code:8207709000

- Production Capacity:50000PCS,Month

Description

Coating

Color

Coating Temperature

Thickness (um)

HV

Application Temperature

Friction coefficient

TiAlN

4. Packing

Brand Laser printed on cutter shank, 1 PCS in a plastic tube, 10 PCS a group

5. Delivery time

Keep stock for regular types

Samples: 3 - 5 days

Regular orders: 7 - 10 days

Standard Sizes

| Order No. | Flute dia (d) | Cutting length ( l ) | Shank dia (D) | Overall length(L) |

| 1.0×2.5×4D×50L | 1.0 | 2.5 | 4 | 50 |

| 1.5×4×4D×50L | 1.5 | 4 | 4 | 50 |

| 2.0×5×4D×50L | 2.0 | 5 | 4 | 50 |

| 2.5×7×4D×50L | 2.5 | 7 | 4 | 50 |

| 3.0×8×4D×50L | 3.0 | 8 | 4 | 50 |

| 3.5×10×4D×50L | 3.5 | 10 | 4 | 50 |

| 4.0×10×4D×50L | 4 | 10 | 4 | 50 |

| 4.5×11×6D×50L | 4.5 | 11 | 6 | 50 |

| 5.0×13×6D×50L | 5.0 | 13 | 6 | 50 |

| 5.5×13×6D×50L | 5.5 | 13 | 6 | 50 |

| 6.0×15×6D×50L | 6.0 | 15 | 6 | 50 |

| 6.5×15×8D×60L | 6.5 | 15 | 8 | 60 |

| 7.0×17×8D×60L | 7.0 | 17 | 8 | 60 |

| 7.5×17×8D×60L | 7.5 | 17 | 8 | 60 |

| 8.0×20×8D×60L | 8.0 | 20 | 8 | 60 |

| 8.5×25×10D×75L | 8.5 | 25 | 10 | 75 |

| 9.0×25×10D×75L | 9.0 | 25 | 10 | 75 |

| 9.5×25×10D×75L | 9.5 | 25 | 10 | 75 |

| 10.0×25×12D×75L | 10.0 | 25 | 12 | 75 |

| 10.5×25×12D×75L | 10.5 | 25 | 12 | 75 |

| 11.0×28×12D×75L | 11.0 | 28 | 12 | 75 |

| 11.5×28×12D×75L | 11.5 | 28 | 12 | 75 |

| 12.0×30×12D×75L | 12.0 | 30 | 12 | 75 |

| 13.0×33×16D×100L | 13.0 | 33 | 16 | 100 |

| 14.0×40×16D×100L | 14.0 | 40 | 16 | 100 |

| 15.0×40×16D×100L | 15.0 | 40 | 16 | 100 |

| 16.0×40×16D×100L | 16.0 | 40 | 16 | 100 |

| 17.0×40×20D×100L | 17.0 | 40 | 20 | 100 |

| 18.0×40×20D×100L | 18.0 | 40 | 20 | 100 |

| 19.0×40×20D×100L | 19.0 | 40 | 20 | 100 |

| 20.0×40×20D×100L | 20.0 | 40 | 20 | 100 |

| 25.0×40×25D×100L | 25.0 | 40 | 25 | 100 |

6. Product

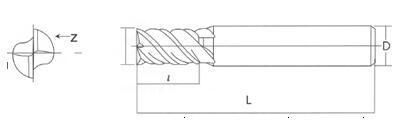

2 flutes Flat End Mill

HRC choice: HRC38-45, HRC45-50, HRC55-58, HRC60-62, HRC65-70

Coating choice: AITiN, AICrSiN, AITiCrSIN, TiSiN, NACO-BLUE

Materials to be cut: original steel, cast iron, Aluminum, copper, graphite, plastics,

Titanium , alloy, harden steel, stainless steel, HSS etc.

| Code No. | Diamter d | Cutting length l | Total length L | Shank D | Flutes Z |

| 2GW1-01002050 | 1 | 3 | 50 | 4 | 2 |

| 2GW1-01504050 | 1.5 | 4 | 50 | 4 | 2 |

| 2GW1-02050500 | 2 | 5 | 50 | 4 | 2 |

| 2GW1-02507050 | 2.5 | 7 | 50 | 4 | 2 |

| 2GW1-03008050 | 3 | 8 | 50 | 4 | 2 |

| 2GW1-04010050 | 4 | 10 | 50 | 4 | 2 |

| 2GW1-04015075 | 4 | 15 | 75 | 4 | 2 |

| 2GW1-04020100 | 4 | 20 | 100 | 4 | 2 |

| 2GW1-05012050 | 5 | 13 | 50 | 6 | 2 |

| 2GW1-06015050 | 6 | 15 | 50 | 6 | 2 |

| 2GW1-06020075 | 6 | 20 | 75 | 6 | 2 |

| 2GW1-06020100 | 6 | 30 | 100 | 6 | 2 |

| 2GW1-06020060 | 8 | 20 | 60 | 8 | 2 |

| 2GW1-08025075 | 8 | 25 | 75 | 8 | 2 |

| 2GW1-08025100 | 8 | 35 | 100 | 8 | 2 |

| 2GW1-010025075 | 10 | 25 | 75 | 10 | 2 |

| 2GW1-010040100 | 10 | 40 | 100 | 10 | 2 |

| 2GW1-012020075 | 12 | 30 | 75 | 12 | 2 |

| 2GW1-012040100 | 12 | 40 | 100 | 12 | 2 |

| 2GW1-014020080 | 14 | 30 | 80 | 14 | 2 |

| 2GW1-014100100 | 14 | 40 | 100 | 14 | 2 |

| 2GW1-016040100 | 16 | 40 | 100 | 16 | 2 |

| 2GW1-018040100 | 18 | 40 | 100 | 18 | 2 |

| 2GW1-020040100 | 20 | 40 | 100 | 20 | 2 |

| 2GW1-06040150 | 6 | 40 | 150 | 6 | 2 |

| 2GW1-08050150 | 8 | 50 | 150 | 8 | 2 |

| 2GW1-010050150 | 10 | 50 | 150 | 10 | 2 |

| 2GW1-012050150 | 12 | 50 | 150 | 12 | 2 |

| 2GW1-014060150 | 14 | 60 | 150 | 14 | 2 |

| 2GW1-016060150 | 16 | 60 | 150 | 16 | 2 |

| 2GW1-018060150 | 18 | 60 | 150 | 18 | 2 |

| 2GW1-020060150 | 20 | 60 | 150 | 20 | 2 |

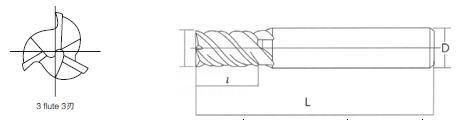

3 flutes Flat End Mill

HRC choice: HRC38-45, HRC45-50, HRC55-58, HRC60-62, HRC65-70

Coating choice: AITiN, AICrSiN, AITiCrSIN, TiSiN, NACO-BLUE

Materials to be cut: original steel, cast iron, Aluminum, copper, graphite, plastics,

Titanium , alloy, harden steel, stainless steel, HSS etc.

| Code No. | Diamter d | Cutting length l | Total length L | Shank D | Flutes Z |

| 3GW1-01003050 | 1 | 3 | 50 | 4 | 3 |

| 3GW1-01504050 | 1.5 | 4 | 50 | 4 | 3 |

| 3GW1-02050500 | 2 | 5 | 50 | 4 | 3 |

| 3GW1-02507050 | 2.5 | 7 | 50 | 4 | 3 |

| 3GW1-03008050 | 3 | 8 | 50 | 4 | 3 |

| 3GW1-04010050 | 4 | 10 | 50 | 4 | 3 |

| 3GW1-04015075 | 4 | 15 | 75 | 4 | 3 |

| 3GW1-04020100 | 4 | 20 | 100 | 4 | 3 |

| 3GW1-05013050 | 5 | 13 | 50 | 6 | 3 |

| 3GW1-06015050 | 6 | 15 | 50 | 6 | 3 |

| 3GW1-06020075 | 6 | 20 | 75 | 6 | 3 |

| 3GW1-06030100 | 6 | 30 | 100 | 6 | 3 |

| 3GW1-06020060 | 8 | 20 | 60 | 8 | 3 |

| 3GW1-08025075 | 8 | 25 | 75 | 8 | 3 |

| 3GW1-08035100 | 8 | 35 | 100 | 8 | 3 |

| 3GW1-010025075 | 10 | 25 | 75 | 10 | 3 |

| 3GW1-010040100 | 10 | 40 | 100 | 10 | 3 |

| 3GW1-012030075 | 12 | 30 | 75 | 12 | 3 |

| 3GW1-012040100 | 12 | 40 | 100 | 12 | 3 |

| 3GW1-014030080 | 14 | 30 | 80 | 14 | 3 |

| 3GW1-014100100 | 14 | 40 | 100 | 14 | 3 |

| 3GW1-016040100 | 16 | 40 | 100 | 16 | 3 |

| 3GW1-018040100 | 18 | 40 | 100 | 18 | 3 |

| 3GW1-020040100 | 20 | 40 | 100 | 20 | 3 |

| 3GW1-06040150 | 6 | 40 | 150 | 6 | 3 |

| 3GW1-08050150 | 8 | 50 | 150 | 8 | 3 |

| 3GW1-010050150 | 10 | 50 | 150 | 10 | 3 |

| 3GW1-012050150 | 12 | 50 | 150 | 12 | 3 |

| 3GW1-014060150 | 14 | 60 | 150 | 14 | 3 |

| 3GW1-016060150 | 16 | 60 | 150 | 16 | 3 |

| 3GW1-018060150 | 18 | 60 | 150 | 18 | 3 |

| 3GW1-020060150 | 20 | 60 | 150 | 20 | 3 |

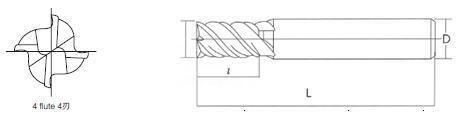

4 flutes Flat End Mill

HRC choice: HRC38-45, HRC45-50, HRC55-58, HRC60-62, HRC65-70

Coating choice: AITiN, AICrSiN, AITiCrSIN, TiSiN, NACO-BLUE

Materials to be cut: original steel, cast iron, Aluminum, copper, graphite, plastics,

Titanium , alloy, harden steel, stainless steel, HSS etc.

| Code No. | Diamter d | Cutting length l | Total length L | Shank D | Flutes Z |

| 4GW1-01003050 | 1 | 3 | 50 | 4 | 4 |

| 4GW1-01504050 | 1.5 | 4 | 50 | 4 | 4 |

| 4GW1-02050500 | 2 | 5 | 50 | 4 | 4 |

| 4GW1-02507050 | 2.5 | 7 | 50 | 4 | 4 |

| 4GW1-03008050 | 3 | 8 | 50 | 4 | 4 |

| 4GW1-04010050 | 4 | 10 | 50 | 4 | 4 |

| 4GW1-04015075 | 4 | 15 | 75 | 4 | 4 |

| 4GW1-04020100 | 4 | 20 | 100 | 4 | 4 |

| 4GW1-05013050 | 5 | 13 | 50 | 6 | 4 |

| 4GW1-06015050 | 6 | 15 | 50 | 6 | 4 |

| 4GW1-06020075 | 6 | 20 | 75 | 6 | 4 |

| 4GW1-06030100 | 6 | 30 | 100 | 6 | 4 |

| 4GW1-06020060 | 8 | 20 | 60 | 8 | 4 |

| 4GW1-08025075 | 8 | 25 | 75 | 8 | 4 |

| 4GW1-08035100 | 8 | 35 | 100 | 8 | 4 |

| 4GW1-010025075 | 10 | 25 | 75 | 10 | 4 |

| 4GW1-010040100 | 10 | 40 | 100 | 10 | 4 |

| 4GW1-012030075 | 12 | 30 | 75 | 12 | 4 |

| 4GW1-012040100 | 12 | 40 | 100 | 12 | 4 |

| 4GW1-014030080 | 14 | 30 | 80 | 14 | 4 |

| 4GW1-014100100 | 14 | 40 | 100 | 14 | 4 |

| 4GW1-016040100 | 16 | 40 | 100 | 16 | 4 |

| 4GW1-018040100 | 18 | 40 | 100 | 18 | 4 |

| 4GW1-020040100 | 20 | 40 | 100 | 20 | 4 |

| 4GW1-06040150 | 6 | 40 | 150 | 6 | 4 |

| 4GW1-08050150 | 8 | 50 | 150 | 8 | 4 |

| 4GW1-010050150 | 10 | 50 | 150 | 10 | 4 |

| 4GW1-012050150 | 12 | 50 | 150 | 12 | 4 |

| 4GW1-014060150 | 14 | 60 | 150 | 14 | 4 |

| 4GW1-016060150 | 16 | 60 | 150 | 16 | 4 |

| 4GW1-018060150 | 18 | 60 | 150 | 18 | 4 |

| 4GW1-020060150 | 20 | 60 | 150 | 20 | 4 |

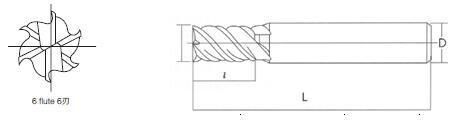

6 flutes Flat End Mill

HRC choice: HRC38-45, HRC45-50, HRC55-58, HRC60-62, HRC65-70

Coating choice: AITiN, AICrSiN, AITiCrSIN, TiSiN, NACO-BLUE

Materials to be cut: original steel, cast iron, Aluminum, copper, graphite, plastics,

Titanium , alloy, harden steel, stainless steel, HSS etc.

| Code No. | Diamter d | Cutting length l | Total length L | Shank D | Flutes Z |

| 6GW1-06016050 | 6 | 16 | 50 | 6 | 6 |

| 6GW1-06025075 | 6 | 25 | 75 | 6 | 6 |

| 6GW1-06036100 | 6 | 36 | 100 | 6 | 6 |

| 6GW1-0802060 | 8 | 20 | 60 | 8 | 6 |

| 6GW1-08032075 | 8 | 32 | 75 | 8 | 6 |

| 6GW1-08042100 | 8 | 42 | 100 | 8 | 6 |

| 6GW1-10025075 | 10 | 25 | 75 | 10 | 6 |

| 6GW1-10042100 | 10 | 42 | 100 | 10 | 6 |

| 6GW1-012030075 | 12 | 30 | 75 | 12 | 6 |

| 6GW1-012042100 | 12 | 42 | 100 | 12 | 6 |

| 6GW1-012055155 | 12 | 55 | 155 | 12 | 6 |

| 6GW1-014040100 | 14 | 40 | 100 | 14 | 6 |

| 6GW1-014065150 | 14 | 65 | 150 | 14 | 6 |

| 6GW1-016040100 | 16 | 40 | 100 | 16 | 6 |

| 6GW1-016065150 | 16 | 65 | 150 | 16 | 6 |

| 6GW1-020045100 | 20 | 45 | 100 | 20 | 6 |

| 6GW1-020070150 | 20 | 70 | 150 | 20 | 6 |

Our Services

More than 2000 products are available. Assembly line production, high standard and strict requirements.

OEM Services Offered

Customized Tools Offered

Free laser marking on tools and boxes Offered

Fast delivery time and Convenient Transportations. We have discount on shipping cost from our courier companies, such as FedEx, DHL, TNT, UPS etc.

Waiting for your contact !