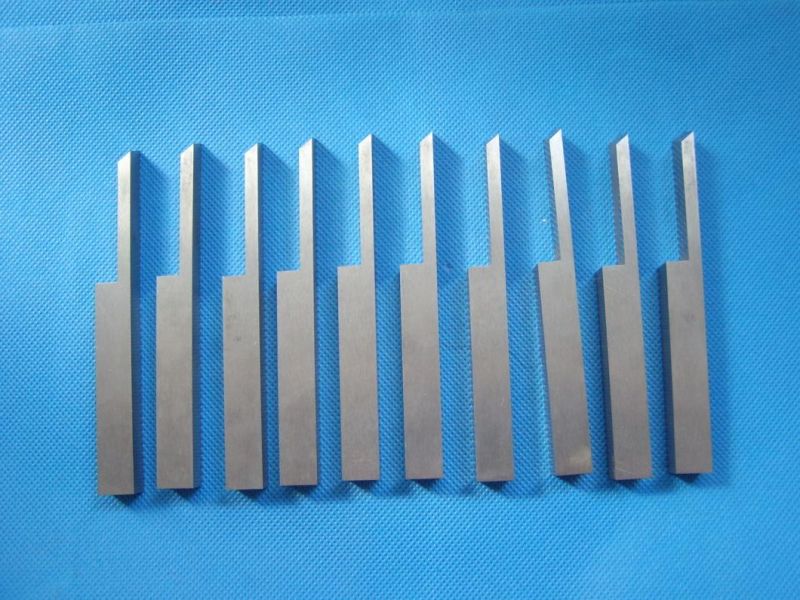

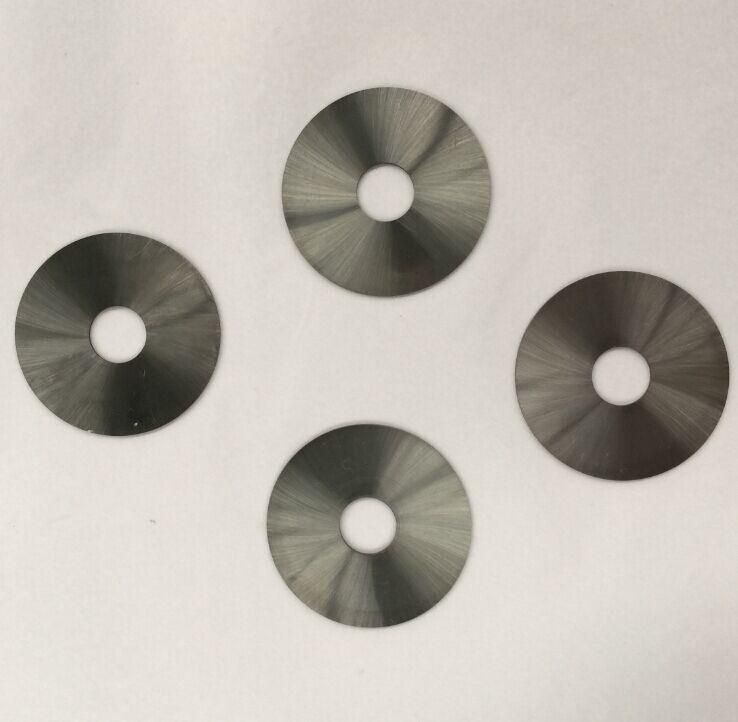

Excellent Quality Tungsten Carbide Cutting Tools

Solid Metalworking LNC. Limited- Type:Cutter

- Size:Customized

- Material:Tungsten Carbide

- Standards:Hra

- Style:Universal Tool

- Structure:Special Type

Base Info

- Model NO.:Customized

- Cutting Process:Turning Tools

- Work Type:Cut Off

- Transport Package:Carton Box

- Specification:ISO

- Trademark:AT CARBIDE

- Origin:Chengdu, China

- HS Code:82090000

- Production Capacity:20, 000 PCS,Month

Description

Basic Info.

Model NO. Customized Cutting Process Turning Tools Work Type Cut Off Transport Package Carton Box Specification ISO Trademark AT CARBIDE Origin Chengdu, China HS Code 82090000 Production Capacity 20, 000 PCS/MonthProduct Description

We are a professional manufacturer of Cemented Carbide Tools, and can supply you with kinds of standard and special standard Cutting Tools.The Cemented Carbide Tools is good at hardness and wear resistance, the tool life always is 3~10 times of the one made by tool steel. The cost-effective is obviously due to the long tool life.

The Cuttig Tools made by Cemented Carbide can be finishing proceed by CNC machines and EDM, so the cutting tools could be designed to different sizes and tolerances.

Carbide grades are as follows:

| Grade | Density | Hardness (HRA) | Bending Strength (/Mpa) | Performance and Application | Equivalent ISO Grade |

| YG3X | 15.0~15.3 | 92 | 1320 | Fine Grain Size, outstanding in hardness, which is used to high speed finishing of cast iron, non-ferrous alloy, and alloy hardened steel, and alloy steel. | K01 |

| YG3 | 15.0~15.3 | 91 | 1200 | Excellent in hardness, and suitable for finishing of cast iron, non-ferrous alloy, and plastic, rubber, etc. | K01 |

| YG6X | 14.6~15.0 | 91 | 1400 | Fine grain size. Excellent in wear resistance. Be used to process ferrous steel (HB<200), glass, hard rubber, cardboard, marble, ceramic copper alloy etc. | K10 |

| YG6 | 14.6~15.0 | 89.5 | 1450 | Be used to process ferrous steel(HB<200),non-ferrous metal, wood, plastic, etc. | K20 |

| YG8 | 14.5~14.9 | 89 | 1500 | Rough and semi-finishing of cast iron, nonferrous metal, wood, plastic, etc. | K30 |

| YG11C | 14.0~14.4 | 86.5 | 2100 | Grade for manufacturing nozzle, wear resistance parts, die insert, mining tool, measuring tool like gauge, micrometer etc | K40 |

| YG15 | 13.9~14.2 | 87 | 2100 | Grade for manufacturing nozzle, wear resistance parts, die insert, mining tool, measuring tool like gauge, micrometer etc | K40 |

| YG20 | 13.4~13.7 | 85.5 | 2600 | Excellent in toughness and suitable for punching mold. | K40 |

| YG20C | 13.4~13.7 | 85 | 2650 | Excellent in toughness and suitable for cold heading, cold punching, cold pressing mold, and punching mold. | K40 |