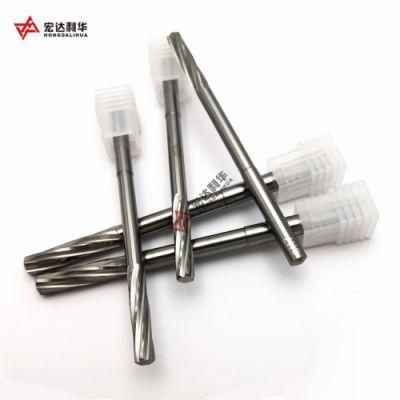

Solid Carbide Spiral Flute Machine Reamer in H7 Suitable for Reaming Steel/Stainless Steel/Cast Iron/Non-Ferrous Materials

Zhuzhou Lihua Cemented Carbide Co., Ltd.- Coating:Coating or Uncoated

- Tooth Form:Spiral Tooth

- Tooth Space:Sparse Tooth

- Structure:Indexable Type

- Material:Cemented Carbide

- Type:Face Milling Cutter

Base Info

- Advantage:Over 20 Years Experience in This Line

- Diameter:1.0 to 20.0mm

- Overall Length:50 to 150mm

- Transport Package:Base on Customer′s Requirements

- Specification:customized

- Trademark:LIHUA

- Origin:Zhuzhou

- Production Capacity:5000kg,Mon

Description

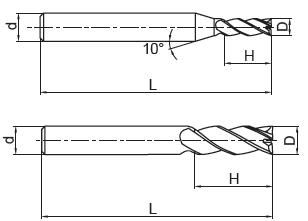

Flute Dia

Shank Dia

Flute Length

Total Length

Super raw material

Co:10 %

Flexural strength:3320N/mm2

Co:10 %

Flexural strength:4000N/mm2

Co:12 %

Flexural strength:4300N/mm2

| Grain Size:0.5um Co:10 % Flexural strength:4300N/mm2 |

Super coating

Company Informations

About Lihua Cemented Carbide

Established in 1990, specialized in production carbide products more than 20 years and located in zhuzhou city which is the hometown of tungsten carbide in China .

Our products sold well to worldwide, has been build a long term relationship with our customers from Italy, Portugal, German, Turkey, USA, Mexico, India, Australia, South Africa etc .

Main Products

Our Main products include : Carbide Screwed Boring Bar, Plates, Rods, Sticks, Bushings, TP nozzles, 3D Printer Nozzles, Saw Blades, End Mills & Drill Bits, CNC inserts, Value Seats, Rotary Burrs, wheel cutters, Grits, Cusomized cutter:woodworking tool, V-cutter, textile cutter, shoes cutter ects. Any kinds of customized carbide products .

Monthly Capacity of 15Ton

We have sophisticated equipments, such as Sintering Furnace, Automatic suppress Machine, Manual Hydraulic Suppress Machine, Ball Mill Machine, Drying Machine, Mixing Machine ect, Our production capacity up to 15 Ton per month. Customized is welcome, customized sample can be ready in 3-5 days and 1 day can deliver for stocks.

Strictly QC

We have a professional QC team follow to the System of ISO9001:2008, Covering the Raw Materials Incoming, Production Processes, Finished Products and Packaging to ensure high quality products output.

Our Exhibitions & Qualifications