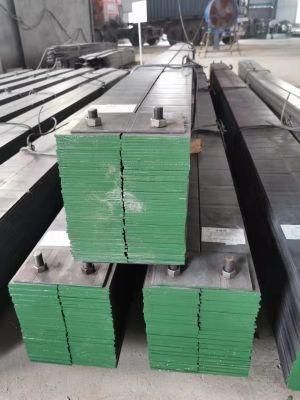

Manufacture Wholesale Gang Saw Blade Granite Gang Saw Steel Blade

XIAMEN PRODRILL EQUIPMENT CO., LTD.- Function:Cutting

- Shape:Gang Saw Blade

- Type:Steel Saw Blade

- Application:Granite Block Cutting to Slab

- Advantage:Wear-Resistant, Long Life

- MOQ:27 Tons

Base Info

- Thickness:4.0mm, 4.2mm, 4.5mm, 4.8mm, 5.0mm

- Usage Way:Dry & Wet Cutting

- Quality:Top

- Specification:4.5*100, 4.5*110, 4.5*120

- Trademark:PRODRILL

- Origin:China

- HS Code:82023910

- Production Capacity:500 Ton,Tons Per Month

Description

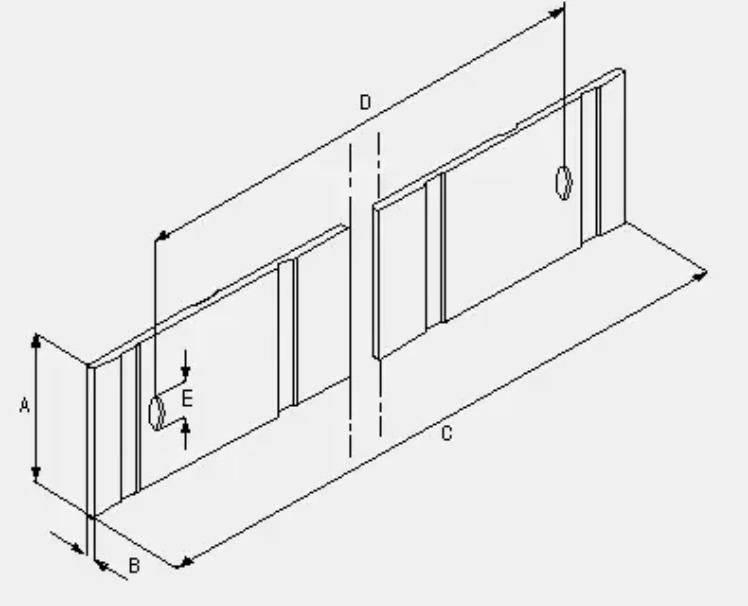

When ordering, please clear the following information to us.

A. Width

B. Thickness

C. Total length

D. Distance between the hole-centers

E. Diameter of holes

Basically requirement of correct application

I.Correct installation

(1). Blades should be parallel with the central line of the blade holder and assuring of blade vertical.

otherwise, which leads to extra large sawing gap, only one side of blade to be abraded,which cause

concave in middle blade and bending severity after a finish of a trolley of granite blocks.

(2).Blade up to enough tension. Blade should be installed tightly between the front heads on blade

holder. After checking verticality, hydraulic extension device should be equipped firstly for individual

extension force to extend the blade at full, or the blade can not be of enough tension. Basically,

tension force is decided by the size of new blades, for example, in total 8 tons for 100×4.5mm,

9.5 tons for 120×4.5mm. If the blade is not up to enough tension,then quivering is too severe

when sawing and concave in middle of blade and bending severity after removal.

II.Appropriate composition of cutting fluid.

(1) In general, the size of grit is 1/4-1/5 of thickness of blade, and small grits are suitable for thin blade, opposite for the thick one.

Otherwise, which may lead to slab surface rough and cutting abilities low.

(2) Appropriate grit capacity and cutting fluid density. Less steel grit input will cause poor cut

abilities and even are not able to saw stone. In contrary, too much accumulated grits in the

gaps will lead to blade running out of order.

III. Proper cutting down speed.

At the beginning when blades are not going into stone, cutting speed should be lower, when

the blade going into stone entirely, speed can be faster. The cutting speed is decided by the

block's hardness. Too low speed will lead to low efficiency, however, too fast speed will cause

the saw blade quivers, electric current of mainframe too large and trouble sawing happens.