Best Quality Bandsaw Blade for Cutting Metal and Steel

HANGZHOU FUWEISI SAW INDUSTRY CO., LTD.- Certification:ISO9001:2008, ISO9001:2000, RoHS, CE

- Tooth Form:B Tooth

- Function:Cutting

- Shape:Band Saw Blade

- Type:Band Saw

- Material:HSS M42

Base Info

- Standards:HRC67-69

- Transport Package:Pallet

- Specification:27x0.9mm

- Trademark:FUWEISI, BOSS CUT

- Origin:Germany Material

- HS Code:8202201000

- Production Capacity:5 Million Meters Per Month

Description

Basic Info.

Standards HRC67-69 Transport Package Pallet Specification 27x0.9mm Trademark FUWEISI, BOSS CUT Origin Germany Material HS Code 8202201000 Production Capacity 5 Million Meters Per MonthProduct Description

Fuweisi International Ltd was established in Lishui city, zhejiang province of China in 2000, with factory for more than 50000 square meters and 660 staff. Company got "Direct-Export license" in 2005, and now is a SGS certified supplier.

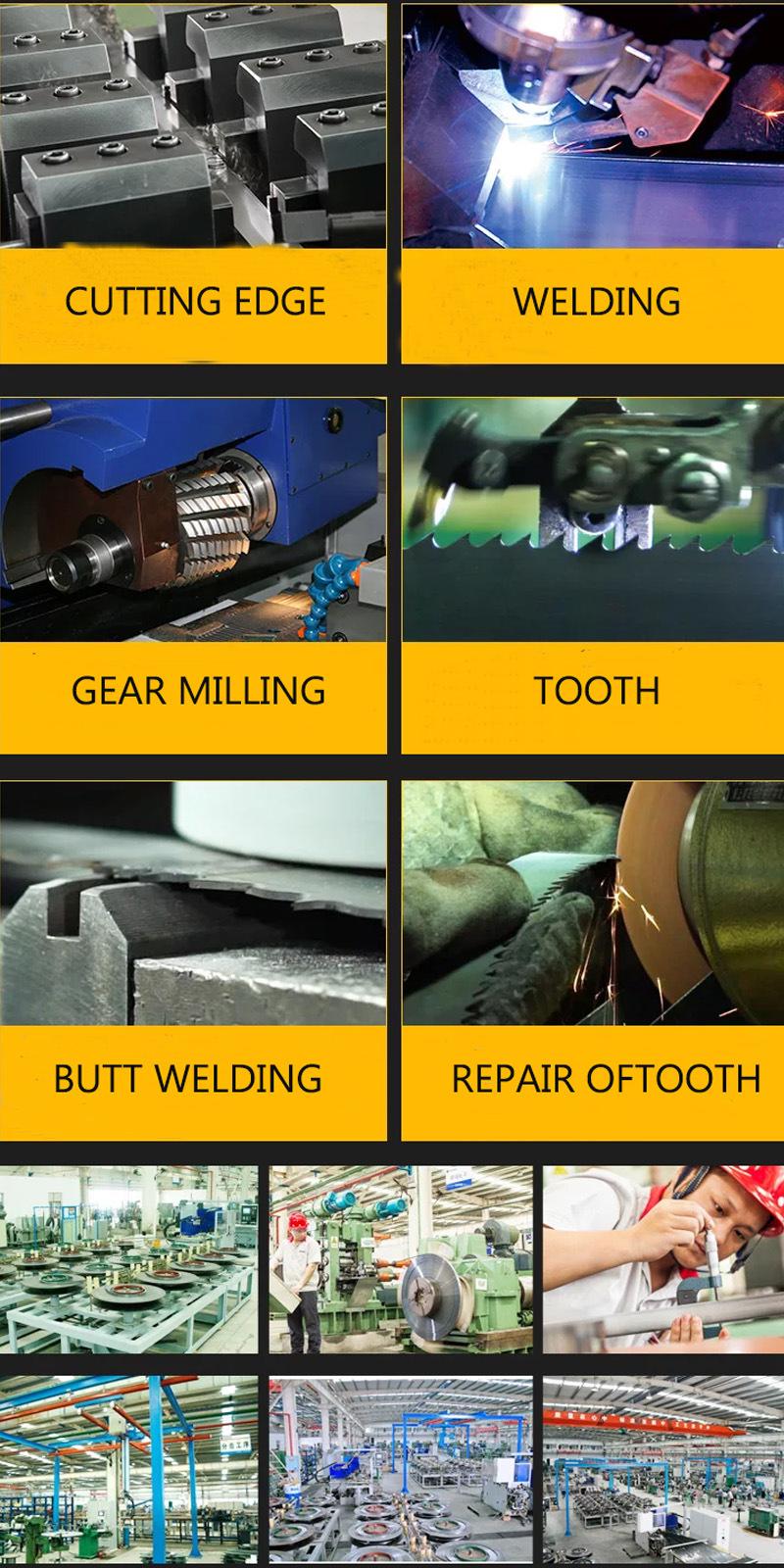

Company mainly produce M42 bimetal band saw blade and HSS circular circular saw blade. With production capacity of 25 million meters for band saw blade annually and 300, 000 PCS for HSS circular saw blade each year.

For M42 band saw blades, we are manufacturing full dimension and TPI, and we only use raw material from Europe, USA and Japan, all our production machinery are from Europe or best machine tool supplier in China, and we have a very strict QC system, each meter of blade are monitored by computer and examing tools. We have 50 people only are responsible for quality checking, and have more than 100 band saw blade engineers in our plant. So we are very proud of our blades manufactured.

For HSS saw blades, what we do is from 32mm to 600mm for diameter and in all thickness and bore sizes, We only use certified HSS M2 and M35 material, and manufactured by most moden CNC machinery, together with Swedeen PVD coating process. And tooth grinding done by CNC grinding machine in order to gurantee tooth sharp and durable in all tooth number & forms.

Thanks for the hard working of our staff and kind support of customers, company have benn enjoying a good reputation home and abroad. In overseas, customers are in more than 20 countries and regions, such as Korea, India, USA. Brazil. Russia, etc.

Looking at future, customers from home and abroad are welcomed to establish a mutual beneficial long term co-operation.