Shanghai Saw Star Trading Co., Ltd.

Wholesale and retail of mechanical equipment and accessories, packaging materials, metal materials, electronic products, electromechanical equipment, rubber and plastic products, hardware and electrical equipment, electric tools, instruments and meters, electrical equipment, stationery, general labor protection articles and daily necessities. [for projects subject to approval according to law, business activities can be carried out only with the approval of relevant departments]

For M42 band saw blades, we are manufacturing full dimension and TPI, and we only use raw material from Europe, USA and Japan, all our production machinery are from Europe or best machine tool supplier in China, and we have a very strict QC system, each meter of blade are monitored by computer and examing tools. We have 50 people only are responsible for quality checking, and have more than 100 band saw blade engineers in our plant. So we are very proud of our blades manufactured.

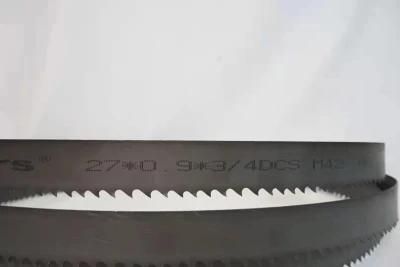

BEERS brand Bi-metal band saw blade is made of imported Germany M42 tooth material and backing spring steel material. HRC of blade could be reached to 67-69. This special band saw blade is used for cutting beams, pipes and profiles. And the special tooth geometry is resistant againist vibrations and heavy irregular mechanical strain arising with the metioned applications.

The heating process treatment like all other steps in our production system, are daily monitored by our lab technicians in the metallography dept this gurantees that all our band saw blades match the previously defined quality standards. Our

Research and development team assure a steady evolution of the processes in order to obtain the best quality performance during all phases

A new saw blade must be run in before use on site. The service life of a non running-in or non running-in well saw blade is one third or less of that of a running- in well saw blade.

1. Feed during the running-in period should be 20-30 % of the proper amount.

2. The running-in period is approximately 5% to 10% of the life expectancy.

3. The belt speed during running-in should be 20-30 % of that during the normal cutting.

4. Sawbands should experience a gradual transition from running-in to normal cutting. Do not increase the feed and belt speed too much each time.

For M42 band saw blades, we are manufacturing full dimension and TPI, and we only use raw material from Europe, USA and Japan, all our production machinery are from Europe or best machine tool supplier in China, and we have a very strict QC system, each meter of blade are monitored by computer and examing tools. We have 50 people only are responsible for quality checking, and have more than 100 band saw blade engineers in our plant. So we are very proud of our blades manufactured.

BEERS brand Bi-metal band saw blade is made of imported Germany M42 tooth material and backing spring steel material. HRC of blade could be reached to 67-69. This special band saw blade is used for cutting beams, pipes and profiles. And the special tooth geometry is resistant againist vibrations and heavy irregular mechanical strain arising with the metioned applications.

The heating process treatment like all other steps in our production system, are daily monitored by our lab technicians in the metallography dept this gurantees that all our band saw blades match the previously defined quality standards. Our

Research and development team assure a steady evolution of the processes in order to obtain the best quality performance during all phases

A new saw blade must be run in before use on site. The service life of a non running-in or non running-in well saw blade is one third or less of that of a running- in well saw blade.

1. Feed during the running-in period should be 20-30 % of the proper amount.

2. The running-in period is approximately 5% to 10% of the life expectancy.

3. The belt speed during running-in should be 20-30 % of that during the normal cutting.

4. Sawbands should experience a gradual transition from running-in to normal cutting. Do not increase the feed and belt speed too much each time.

Product List