Manufacturer 360mm Panel Sizing Woodworking PCD Circular Saw Blade

Xiamen Lingrui electromechanical Co., Ltd.- Certification:ISO9001:2008, ISO9001:2000

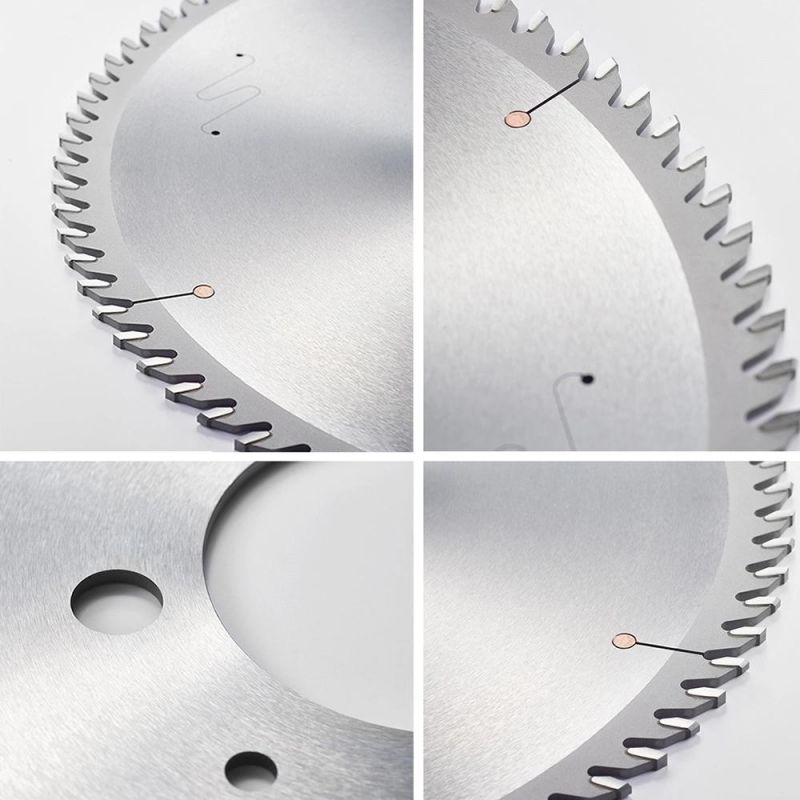

- Tooth Form:Tpp

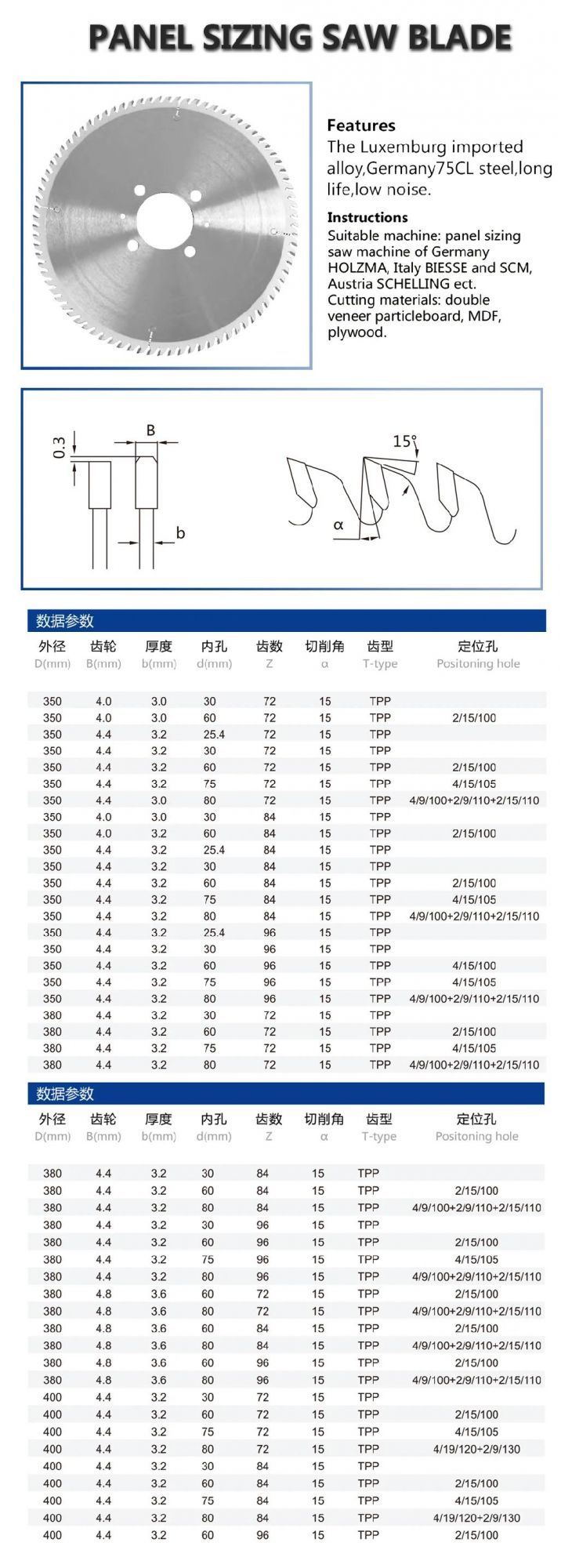

- Diameter:350-380mm

- Function:Cutting

- Shape:Circular Saw Blade

- Coating:as Shown or Customized

Base Info

- Type:Carbide Saw Blade

- Model No:350-380mm

- Thickness:3-3.2mm

- Quality Grade:Professional Grade

- Application:Cutting Wood

- Customized Support:OEM, ODM, Obm

- Transport Package:Carton or Blister Packing

- Specification:customization

- Trademark:as show or customization

- Origin:China (Mainland)

- Production Capacity:5000000,Year

Description

Basic Info.

Type Carbide Saw Blade Model No 350-380mm Thickness 3-3.2mm Quality Grade Professional Grade Application Cutting Wood Customized Support OEM, ODM, Obm Transport Package Carton or Blister Packing Specification customization Trademark as show or customization Origin China (Mainland) Production Capacity 5000000/YearProduct Description

Applicable machine: Germany homag, Italy bia, Italy SCM, Austria Scheling, Taiwan Taiwan exhibition, Taiwan Yuanming, Nan Xing, Extreme east, Zheng Tai, Taiwan ring hongFeatures: Luxembourg imported alloy +, Germany 75Cr1 steel plate, long life, ultra low noise.

Cutting materials: cork, hardwood, medium thickness board, particleboard, single side bonded particleboard, double side bonded particleboard, single side bonded MDF board, plywood, fiberboard, etc.

The electronic cutting saw blade produced by our company has the advantages of material saving, smooth surface cutting, no burr, no edge breakage and so on.

What is an electric split saw?

Electronic saw also known as electronic cutting saw, the use of automatic PC computer or NUMERICAL control program control, man-machine integration operation, in touch screen input to open data, automatic machine operation, the need to process the plate precision cutting machinery.

In recent years, with the rapid development of plate processing industry and more and more strict requirements for plate cutting, the traditional ordinary saw has been difficult to meet the production needs of enterprises. Ordinary opening saw cutting efficiency is low, precision is not enough, low security, push table saw and other ordinary opening saw in the face of high efficiency production line is powerless, hinder the further development of enterprises. The emergence of electronic saw effectively solves this kind of problem, electronic saw adopts manipulator clamping automatic feeding, automatic positioning size precision cutting

Scope of use: electronic saw can be widely used in particleboard, density board, MDF board, gypsum board, circuit board, aluminum board, copper clad board, acrylic board, plastic board, aluminum plastic board, ABS board, PVC board and other boards precision cutting.

· Common saw blade profile

Alloy saw blade commonly used tooth shapes are left and right tooth (alternate tooth), flat tooth, ladder flat tooth (high and low tooth), inverted trapezoid tooth (inverted conical tooth), dovetail tooth (hump tooth), and rare industrial grade three left and one right, left and right flat tooth.

1. The left and right teeth are widely used, with fast cutting speed and relatively simple grinding. Suitable for cutting and cross sawing all kinds of soft and hard solid wood profiles and density board, multilayer board, particleboard, etc. The left and right teeth with anti-rebound protection teeth are dovetail teeth, which are suitable for longitudinal cutting various boards with tree joints; The left and right tooth saw blade with negative front Angle is usually used for panel sawing because of its sharp edge and good sawing quality.

2. Flat tooth saw mouth is rough, cutting speed is slow, grinding is the most simple. It is mainly used for ordinary wood sawing with low cost. It is mostly used for aluminum saw blades with small diameter to reduce adhesion during cutting, or for slotting saw blades to keep groove bottom flat.

3. Ladder flat tooth is a combination of trapezoid tooth and flat tooth, grinding is more complex, can reduce veneer crack phenomenon when sawing, suitable for all kinds of single and double veneer wood-based board, fire board sawing. In order to prevent adhesion, aluminum saw blades with more teeth are also used.

4. Inverted ladder teeth are often used in the slot saw blade of cutting board saw bottom. When cutting the wood-based board with double veneer, the slot saw adjusts the thickness to finish the grooving of the bottom, and then the main saw completes the cutting of the plate, so as to prevent edge collapse.

To sum up, saw solid wood, particleboard, dense board should be selected around teeth, can be sharp wood fiber tissue cut off, smooth incision; In order to keep the bottom of the groove flat slot, flat tooth shape or left and right flat combination teeth; Sawing stick panel, fire board generally choose ladder flat teeth, computer cutting saw due to saw cutting rate, alloy saw blade diameter and thickness are relatively large, the diameter of about 350-450mm, thickness between 4.0-4.8mm, most of the ladder flat teeth, in order to reduce edge collapse, saw marks.

FAQ:1. What terms of payment are acceptable?

A: Normally we accept L/C, T/T and Western Union.

2. How can we be your agent in our country?

A: Please inform us your detailed company, we will discuss and propose helpful suggestion for you, and to find the best solution for you.

3. Do you offer free samples?

A: Normally we do not offer free samples, but we could properly adjust according to detailed requirement.

4. How is your quality?

A: We have a very seriously control system. We guarantee the high performance of our products.

5. When you can reply to me when I send you an Inquiry?

A: We promise to reply within 24 hours( including holidays) on receipt of your inquiry.